|

|

||

|

||||||||||||||||||||||||||||||||||||

| |

||||||||||||||||||||||||||||||||||||

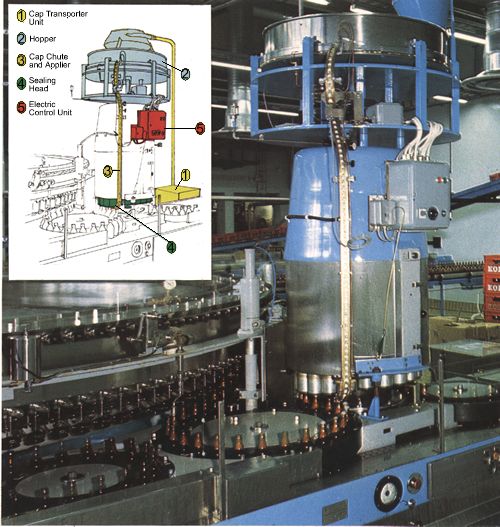

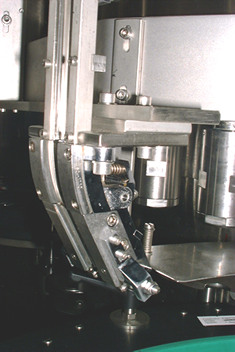

Technical Description of the Conversion KitThe MaxiCrown Conversion Kit can be installed in most types of crowners and other sealing machines with capacities up to 60 000 bottles per hour. Our reference lists are covering more than 100 installations of the MaxiCrown Conversion Kit. Our customers confirm equal reliability and efficiency as for crown corks. The Conversion Kit is

designed for efficient sealing of different types of ring pull caps

as MaxiCrown, Ring Crown and Rip Cap of sizes 26, 33, 38 and 42

mm. The MaxiCrown Conversion Kit has been carefully adapted to the

new MaxiCrown cap, made of aluminium

shell and PE ring (in Japan named Maxi-PGC), to provide optimal

sealing. The sealing machines are manufactured and supplied by us

(i.e., MaxiCrown Sealing Machines

AB in Sweden), that means by technicians with many years of

experience from this specific sealing technique.

The Conversion Kit can be installed either in lines at use with fillers or in new sealing machines in cooperation with the actual manufacturer of filling lines. The optimal flexibility and use of the whole filling line will be achieved by installing the MaxiCrown Conversion Kit in a separate turret, allowing the options of sealing glass bottles with crown corks and glass and plastic bottles with MaxiCrown. By specializing on MaxiCrown sealing machines and making use of our long experience of this technique, we are able to offer our customers competitive prices and secured quality. Conversion kit componentsThe MaxiCrown Conversion Kit has 5 components:1. Cap Transporter

Unit 2. Hopper 3. Cap Chute and Applier

4. Sealing Head

5. Electric Control

Unit

|

||||||||||||||||||||||||||||||||||||

| |

||||||||||||||||||||||||||||||||||||

Sealing PerformanceCapacity High efficiency Early application Plastic bottles Testing of carbonation

retention |

||||||||||||||||||||||||||||||||||||

| |

||||||||||||||||||||||||||||||||||||

Installation and Service

|

||||||||||||||||||||||||||||||||||||

| Copyright © 2002, MaxiCrown SM AB. All rights reserved. |

For

more information, contact: info@maxicrown.se

|

|

MaxiCrown

Sealing Machines AB

|

|